We provide solutions to the challenges of precision dimensional metrology

We offer several engineering services, including contract measurement, training, consulting, and providing professionals (interim). Our engineering capabilities cover solving complex measurement tasks, comprehensive training for metrology professionals, developing and managing measurement room processes, coordinating the interpretation of technical drawings across departments (design, manufacturing, quality assurance), and providing on-site project support.

Our products are exclusively high-quality tools and devices supplied by German partners, including a complete product support provided by us. Our offers include GOEKELER styli and accessories, dk FIXIERSYSTEME fixture components and systems, MAHR handheld measuring devices, and custom metrology equipment.

CONTRACT MEASUREMENT

ACCREDITED TESTING LABORATORY

Our testing laboratory is the FIRST and ONLY one in Hungary accredited by the National Accreditation Authority in the field of precision dimensional measurement technology (ISO 17025).

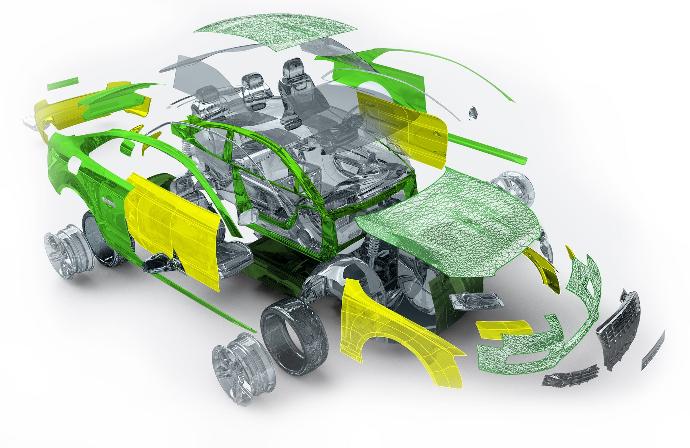

Coordinate measuring machine, 3D scanner, roughness tester.

EXPERIENCE

Trainings and services

provided by highly qualified

engineers.

CUSTOMER FOCUS

Our goal is always to

ensure customer

satisfaction.

FLEXIBILITY

We tailor our trainings

and services to meet our

clients' needs.

TRAINING

EUMETROLOGY ACADEMY

Manufacturer-independent theoretical trainings with modern course materials and practical sections. Technical drawing interpretation, Coordinate metrology, Roughness measurement, and AUKOM trainings.

Courses on Calypso, Caligo, PolyWorks, MarWin, and AccTee.

PRODUCTS

FROM GERMAN PARTNERS

We exclusively sell high-quality products supplied by our German partners, offering comprehensive product support at a cost-effective price. Our portfolio includes GOEKELER styli and accessories, dk FIXIERSYSTEME fixture components and systems, and the full range of MAHR handheld measuring devices.

SERVICES

FROM EXPERIENCED ENGINEERS

We provide expert solutions for metrology-related and other challenges, special cases, and complex issues through our experienced engineers. Our services include contract programming, consulting, on-site support, supply assistance, providing professionals (interim), and stylus repairs.